Heat Treated Pallets & Crates

J&L is ISPM #15 certified to heat treat your wooden pallets and crates that need to be exported out of the country.

We have a truckload size kiln on-site to provide fast turnarounds for our customers in need of small to large heat treating jobs.

Product Wrapping

J&L offers the option to wrap your products in VCI film. Ask about our on-site build options where we wrap and crate around your product on-site!

Heat Treated for Your Products Export Needs

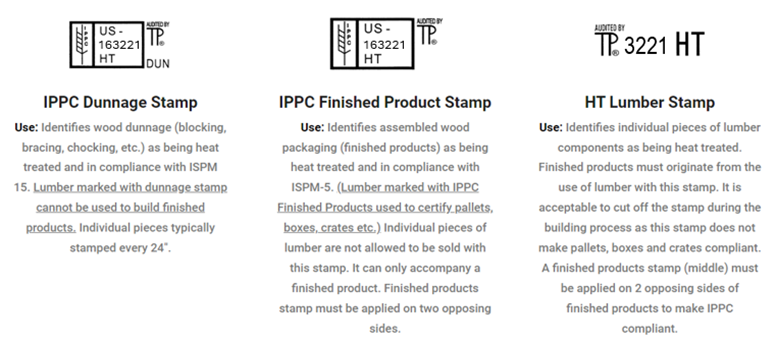

If you’re shipping products abroad, ensuring they’re properly heat-treated is crucial. This means not only heat treating the products themselves, but also stamping the pallets and crates they’re shipped to get through customs reliably. To prevent any pests from damaging your products or infecting the destination country, heat treatment for pallets is essential.

Our company strictly adheres to ISPM 15 requirements, which are mandatory in most countries. But we don’t stop at just heat-treating the pallets and crates. We also provide proper stamps, including the correct country, treatment provider, and treatment codes, to ensure hassle-free shipping.

Experienced Commitment to Your Satisfaction

When you want a company that knows pallets, look no further than J&L Wood Products. We’ve been around since 1968, and we strive to fulfill all your pallet and wood packaging needs. With an extensive inventory and the ability to meet both large and small orders, we can also provide on-time delivery and cost-saving discounts.

J&L delivers heat treated pallets to Ohio, Kentucky, and Indiana in areas such as Dayton, Cincinnati, Columbus, Toledo, Louisville, Lexington, and Indianapolis.

Whether you want standard or custom heat-treated pallets, let us help. Please call us at 937-667-4064 to order your pallets, as well as ask any questions or concerns you may have about our pallets and products.

Custom Tailored to Your Specific Needs

We don’t just heat treat and stamp pallets — we can also custom design them as well. Just let us know what your specific pallet needs are, and we’ll gladly design, heat treat, and stamp them for you.